-

Product

-

Two-components nano ceramic room temperature Paint

-

Replacement

-

Two-parts epoxy coating, wood paint, cement paints, etc.

-

Curing

-

1hr surface dry; 24hr. surface hardness >H; 4H after 7 days, adhesion 5B

-

Salt Spray Test

-

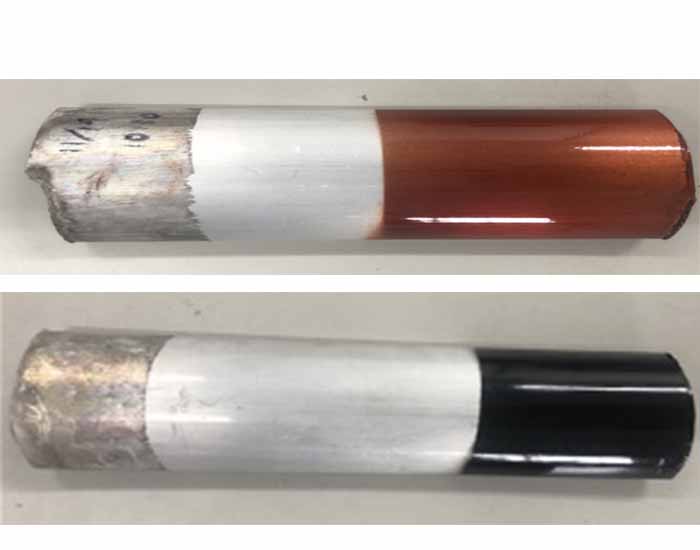

2,000hr./ AI6061/ 8~15µ

-

Surface Hardness

-

>4H

-

Chemical Durability

-

Good for solvents, weak acid and base

-

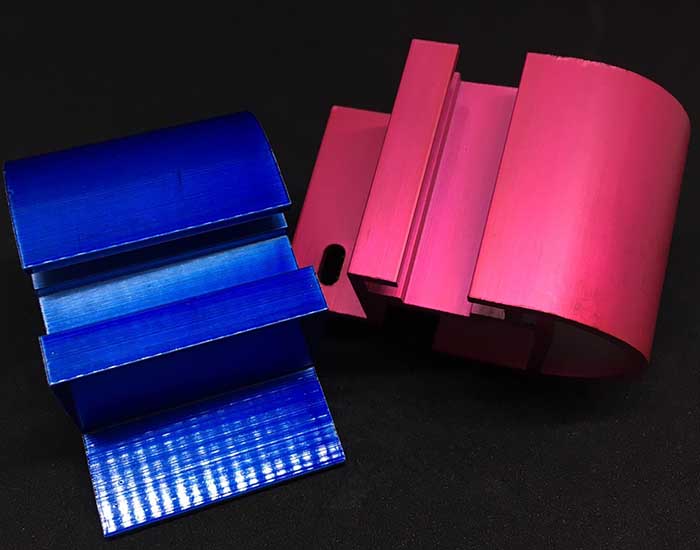

Color

-

Multiple selections of colors. Can be transparent to show the metal bright surface

-

Substrate

-

Aluminum, stainless, carbon steel, copper, and all kinds of metals; glass, ceramics, wood, cement, plastics, composites, etc..